TECHNOLOGY

Cyanoacrylate monomers and products for tomorrow - Status Quo stops here

Since our inception in 2013, we are proud of our achievements in advancing technological developments in Cyanoacrylates (CAs) across the board – Process, Products and Packages. Whereas AFINITICA is young in years we are seasoned in expertise with a high pedigree and more than 70 years of collective technico-commercial experience in the area of specialised adhesives chemistry and applications.

Our strategy to invoke change started with Process Technology. Before the advent of our breakthrough in CA processing only one single mass production process existed that had not overtly changed in 60 years and that was focused principally on production of a single monomer – Ethyl CA (ECA) that is today almost a commodity. We opted to reject the status quo that accepted reactive monomers could only be made by first allowing them to polymerise during manufacture, and that the only way to recover monomer was to subsequently crack apart polymers with large inputs of expensive energy in a process that also created byproducts and much residue. Such sledgehammer approaches in our view also limited the scope of the type of monomers that could be realisable in a practical manner, for example – how could a CA molecule with thermally resistance be made if the process to make it relied on the thermal susceptibility of its polymer? And so to our 'no-crack' CA Process Technology – we filed our first patent application already in 2013 in this very important step in the evolution of the rich history of CAs. Our process uses commodity raw materials and gentle techniques to isolate directly a plethora of cyanoacrylate types and even certain methylidene malonates, in high yield and in high purity - no need to smash up polymers into the beautiful small molecules. Through this approach we have optimized convenient synthesis of important odorless alkoxyalkyl CAs, we have isolated pure high boiling CAs such as medical grade 2-Octyl CA, we have produced solid mono- and di-functional bis- and mixed functionality CAs, and doubled the yield of some known speciality CAs such as the superhydrophobic trimethylsilylmethyl CA. All such molecules fuel our Product Development programs allowing AFINITICA to create novel materials and high performing differentiated products.

Products

Process technology has not been our sole focus of course - we have already filed three new product patent applications and are in the throes of filing several more – CA innovation is in our viens. Not only do we reject the status quo in process technology, but also we demonstrate the considerable value available to our customers by promoting the apparent oxymoron of dual curing CAs – instant adhesives with an extra punch. This is a key AFINITICA strategy. In this regard we offer a spectrum of 2-Part CAs that range from fast adhesives that can cope with any substrate topography yet give strong bonds, to versions customized to offer superior adhesion to specific and problematic substrates like Aluminium or ceramics, to CAs that are not just excellent adhesives – but cure as shrinkage-controlled fast filling materials that enable instant repair and almost immediate machinability, to materials that have ultra-low moduli which flex and stretch to hundreds or even thousands of percent elongation with elastic recovery – and there is more to come. These are the ‘new-look CAs’ – materials that only now combine inconceivable properties with the unique instantaneous curing of the remarkable ‘superglues’.

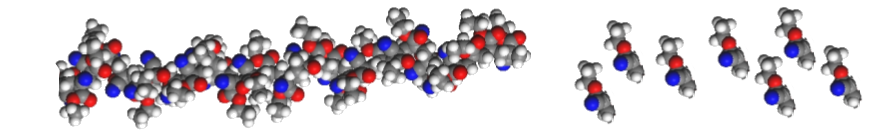

Our 2-Part CAs collection is but one approach to dual cure CAs that exploits the addition of adhesion promoters and catalysts for deep curing that bring the benefits of speed with enhanced properties. Light cure combined with instant cure is another approach. Our goal is to lead the field in Light Curing CAs with unprecedented technological developments enabled by exploiting novel initiating techniques combined with the very special bi-functional and molecular hydrid CAs that only AFINITICA can readily access. The light cured materials we produce can be soluble hompolymers, interpenetrating networks, or insoluble crosslinked homo- or co-polymers that enable multiple applications from temporary or durable industrial, medical or cosmetic rapid tack-free coatings, to fast structure forming bulk curing adhesives and resins.

Our customers still demand solutions to fast reacting safe adhesives applicable to large areas and our process technology ensures the supply of non-irritant, non-staining odorless CA monomers and specialized formulations derived from these including accelerated gel based products. Single component ECA based materials are of course available also from AFINITICA – but only of the highest quality derived from monomers free from starting materials and calibrated by specialized in-house techniques for an optimized balance between speed and shelf-life.

On the activator side - we have addressed the treatment of acidic, cure inhibiting substrates such as the hard woods, easy-to-apply primer with long on-part lifetime. New approaches to priming of other difficult substrates is firmly on our radar and under investigation in our labs.

Packaging

One thing instant adhesives are great at is bonding most everything – even when not intended. We have taken end-user feedback seriously and present our 2-Part adhesives in ergonomic syringes designed for the precision of application demanded by Dental Practioners – but now these in your hands – you deliver what you need, where you need it, mixed automatically – nothing to touch - professional solutions for everyday use. Once done, you can safely dispose of cured solid material in a small plastic part, reclose your pack and be confident that when you wish to re-use, you will have the same result, each time, every time and with no waste, no clogging and no mess – prefect results and cost-efficient use of full contents.

For single component adhesives we do not compromise on quality either and use the most appropriate packaging available for long shelf life products. In tube format we have access to technology that prevents product overrun from gels and we also offer some unique gels in laminated plastic tubes with novel twist cap dispensers.

Literature

We are keen to learn, improve and listen to our customers. Our philosophy is to apply as much collective knowledge to solve problems and deliver solutions that delight and surprise our end users. Since it gives us pleasure to learn from the great research efforts of the past, we believe wholeheartedly in the sharing of information for the future rather than ‘hoarding it, in case it may be useful some day’. For that reason we invite you to use our open source datatbase as a community with the sole purpose to advance the wonderful world of CA technology and to foster discussion, advancements and still further co-developments.